Stormsure

Stormoprene Marine Grade 2-Komponenten-Kontaktkleber (5L)

Stormoprene Marine Grade 2-Komponenten-Kontaktkleber (5L)

Geeignete Materialien

Verfügbarkeit für Abholungen konnte nicht geladen werden

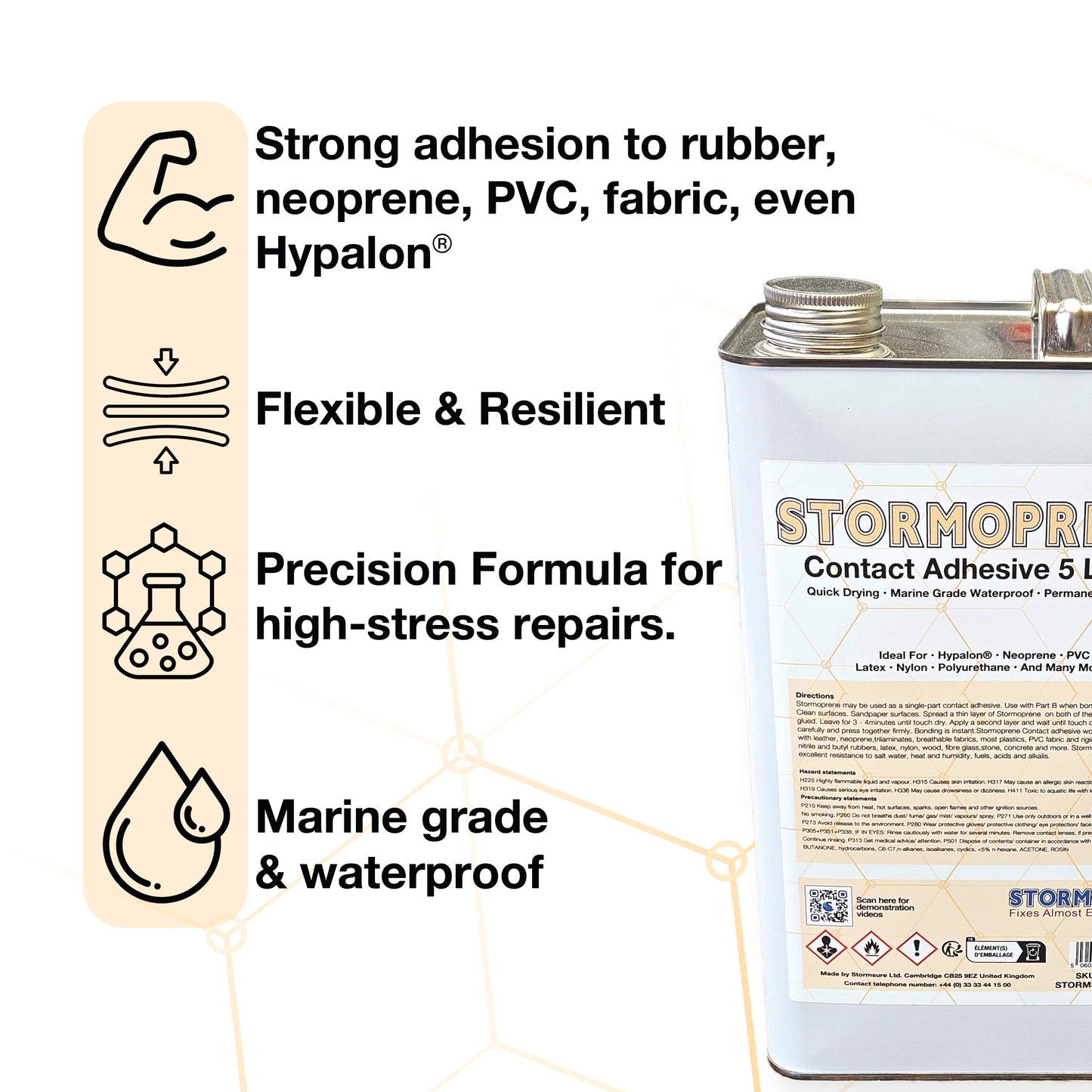

Stormoprene™ Marine Grade Contact Adhesive ist ein speziell formuliertes, zweikomponentiges Klebstoffsystem auf Polychloroprenbasis, das für die Hochleistungsverklebung von Hypalon und anderen natürlichen und synthetischen Kautschukoberflächen entwickelt wurde, wo in anspruchsvollen Anwendungen hochfeste Verbindungen erforderlich sind.

Es ist für die Herstellung und Reparatur von RIBs, Schlauchbooten, Rettungsinseln, Tauchanzügen, Neoprenanzügen und anderen maritimen und industriellen Anwendungen konzipiert, die Beständigkeit gegenüber Salzwasser, Öl, Kraftstoffen und ähnlichen Umgebungen erfordern.

Hauptmerkmale

- Einfach zu mischendes Zweikomponentensystem inklusive Aktivator-Härter.

- Einfaches Auftragen mit Pinsel oder Rolle.

- Kontaktverbindungen in 10 bis 15 Minuten, vollständige Aushärtung in 48 Stunden.

- Ungeöffnet ist die Mischung 3 bis 12 Monate haltbar. Die Verarbeitungszeit des gemischten Klebstoffs beträgt ca. 3 bis 4 Stunden.

Der Klebstoff kann als Einkomponentenkleber auf vielen Textilien verwendet werden. Beim Verkleben von Hypalon-Gewebe muss der Aktivator jedoch mit dem Klebstoff vermischt werden.

Verbindet Hypalon sicher

Dieser speziell für die Verklebung von Hypalon entwickelte Klebstoff berücksichtigt die einzigartigen Eigenschaften des Materials. Hypalon ist strapazierfähig, flexibel und beständig gegen Chemikalien, extreme Temperaturen und UV-Licht. Genau diese Eigenschaften erschweren jedoch die Verklebung. Stormoprene wurde speziell entwickelt, um eine starke und zuverlässige Verbindung auf Hypalon-Oberflächen zu gewährleisten.

Widersteht extremen Umweltbedingungen

Viele Hypalon-Produkte sind extremen Bedingungen wie Salzwasser, Kraftstoffen, Chemikalien, Hitze und intensiver Sonneneinstrahlung ausgesetzt. Boote, Fender, Lastkähne und Neoprenanzüge unterliegen in diesen Umgebungen einem erheblichen Verschleiß. Dieser Klebstoff ist temperaturbeständig von -30 °C bis 120 °C und bietet eine ausgezeichnete Beständigkeit gegenüber Meerwasser und Chemikalien, wodurch auch unter anspruchsvollen Bedingungen eine sichere Verbindung gewährleistet wird.

Gebrauchsanweisung

- Komponenten A (Klebstoff) und B (Härter) etwa fünf Minuten lang vermischen. Im angegebenen Verhältnis oder im Gewichtsverhältnis 25:1 mischen.

- Tragen Sie den angerührten Klebstoff mit einem Pinsel, einer Farbrolle oder einer Zahnkelle gleichmäßig auf beide Oberflächen auf. Lassen Sie ihn 5 bis 15 Minuten trocknen oder bis er sich trocken anfühlt.

- Hinweis: Für optimale Haftung empfiehlt sich das Auftragen von zwei dünnen Schichten. Lassen Sie die erste Schicht ca. 20 bis 30 Minuten trocknen, bevor Sie die zweite Schicht auftragen. Lassen Sie die zweite Schicht 5 bis 15 Minuten trocknen.

- Die Oberflächen werden unter möglichst hohem Druck miteinander verbunden, um Lufteinschlüsse zu vermeiden. Die verbundenen Bauteile können innerhalb weniger Minuten weiterverarbeitet werden.

Aktie