Stormsure

Stormoprene 2-Part Contact Adhesive (250ml)

Stormoprene 2-Part Contact Adhesive (250ml)

Couldn't load pickup availability

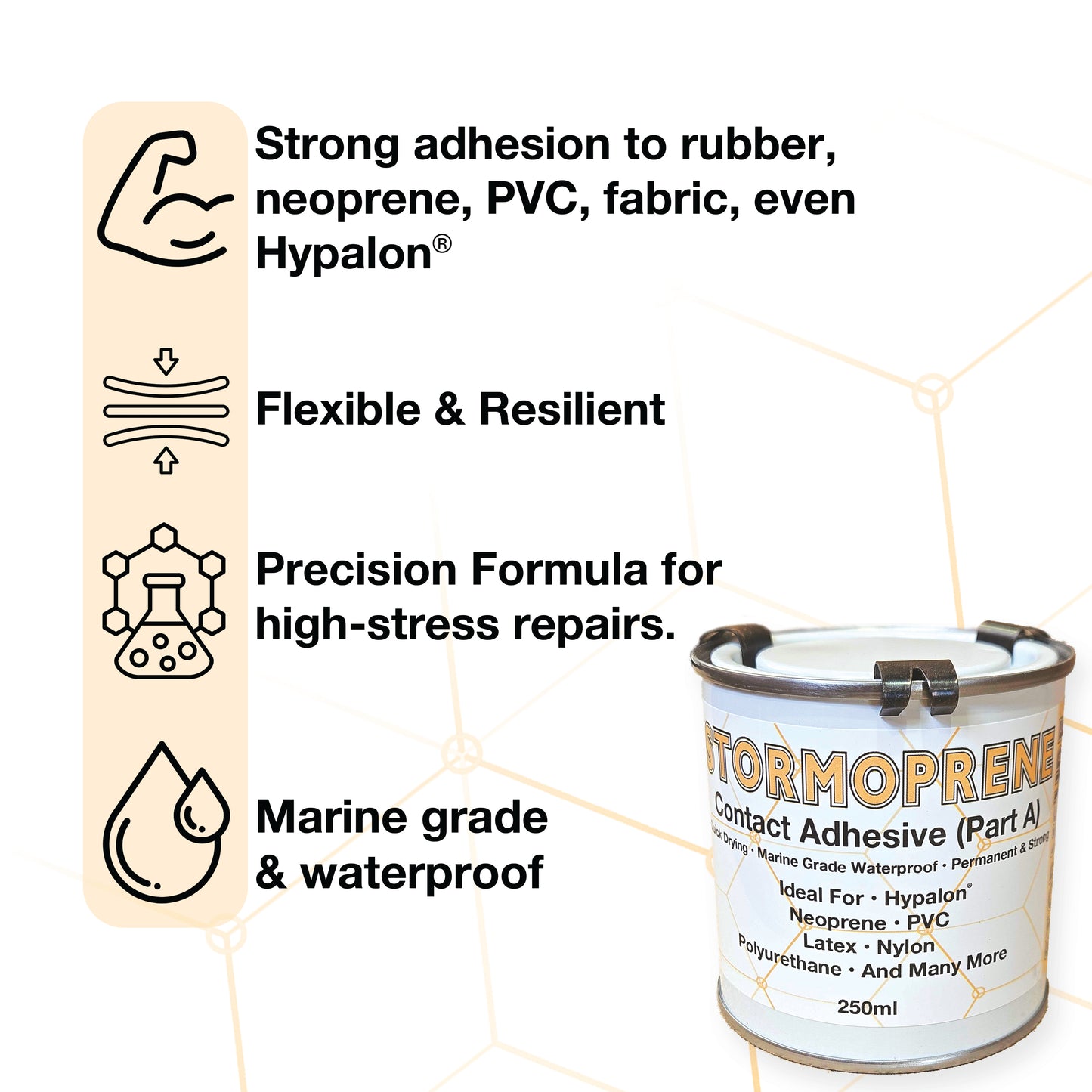

Stormoprene™ Hypalon Adhesive is a specialist two-part polychloroprene-based adhesive system developed for high-performance bonding of Hypalon and other natural and synthetic rubber materials where exceptionally strong, durable bonds are required.

It is formulated for use in the manufacture and repair of RIBs, inflatable boats, liferafts, diving suits, wetsuits, and other marine and industrial products that must withstand prolonged exposure to salt water, oils, fuels, UV light, and extreme environmental conditions.

Key Features:

- Two-part adhesive system: Supplied with activator (curing agent) for maximum bond strength on Hypalon fabrics.

- Single or two-part use: Can be used as a single-component adhesive on many fabrics, with activator required specifically for Hypalon bonding.

- High environmental resistance: Resistant to seawater, oils, fuels, chemicals, heat, and UV exposure.

- Wide temperature tolerance: Maintains bond integrity from approximately -30°C to +120°C.

- Easy application: Suitable for brush or roller application.

- Fast contact bond: Initial bond forms within 10–15 minutes, with full cure achieved in approximately 48 hours.

- Controlled working time: Mixed adhesive has a pot life of approximately 3–4 hours.

Hypalon is widely used in marine products due to its durability, flexibility, and resistance to chemicals and UV radiation. These same properties make it difficult to bond reliably. Stormoprene is specifically engineered to overcome these challenges and deliver secure, long-lasting adhesion on Hypalon substrates.

How to Use:

- Mix components A (adhesive) and B (curing agent) thoroughly for approximately five minutes. Use the supplied proportions or a ratio of 25:1 by weight.

- Apply an even coat of the mixed adhesive to both bonding surfaces using a brush, roller, or serrated applicator.

- Allow the adhesive to dry for 5–15 minutes until dry to the touch.

- For best results, apply two thin coats rather than one thick coat. Allow the first coat to dry for 20–30 minutes before applying the second coat.

- After the final coat has dried for 5–15 minutes, bring the surfaces together using firm, even pressure to eliminate air entrapment.

- Bonded components can be handled within minutes. Full cure is achieved after approximately 48 hours.

Share